CREATED AND RECORDED BY LEADSMART TRAINERS

(scroll down this page to view a video sample of a program)

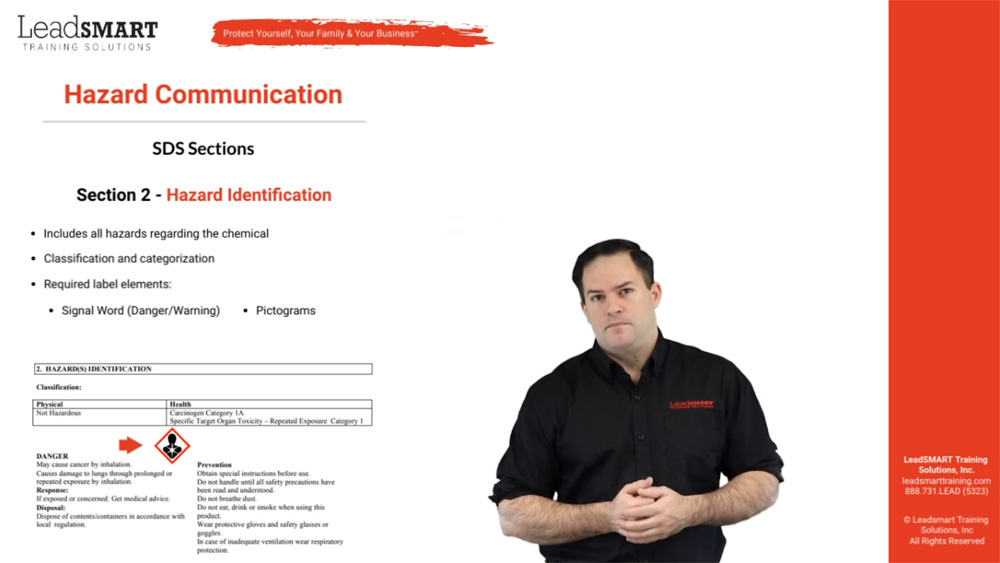

In order to ensure chemical safety in the workplace, information about the identities and hazards of the chemicals must be available and understandable to workers. OSHA's Hazard Communication Standard (HCS) requires the development and dissemination of such information:

CREATED AND RECORDED BY LEADSMART TRAINERS

(scroll down this page to view a video sample of a program)

In order to ensure chemical safety in the workplace, information about the identities and hazards of the chemicals must be available and understandable to workers. OSHA's Hazard Communication Standard (HCS) requires the development and dissemination of such information:

- Chemical manufacturers and importers are required to evaluate the hazards of the chemicals they produce or import, and prepare labels and safety data sheets to convey the hazard information to their downstream customers.

- All employers with hazardous chemicals in their workplaces must have labels and safety data sheets for their exposed workers, and train them to handle the chemicals appropriately.

Video #1 Hazard Communication & How to Read a SDS – Basic Training

- Right to Understand

- GHS – Classification and labeling of chemicals

- SDS – Document to communicate chemical hazard to worker

- Labelling

- PPE

- Training

- SDS – Purpose and background

- SDS – Training by section

- Time: 43 minutes

Video #2 GHS - How to Apply on Jobsites – Advanced

- Primary & Secondary Containers

- Product Identifier

- Supplier Information

- Hazard Information – Pictograms

- How to create a label

- SDS Manual Creation

- Languages

- Locations – On Site or Remote?

- Time: 36 minutes

Registration

Filters

Sort results

Reset

Apply

Name | Price | Quantity | |

|---|---|---|---|

$49.00

|

|||

$49.00

|

How do I access training? Once you place your order for a class, you will receive a link and log-in to that class the following business day. At the end of the course, you’ll be awarded a certificate, which you can download and print to prove your completion of the course. Order $2500 or more in LeadSMART’s Safety-On-Demand videos and receive a 10% discount at checkout.

CREATED AND RECORDED BY LEADSMART TRAINERS

CREATED AND RECORDED BY LEADSMART TRAINERS

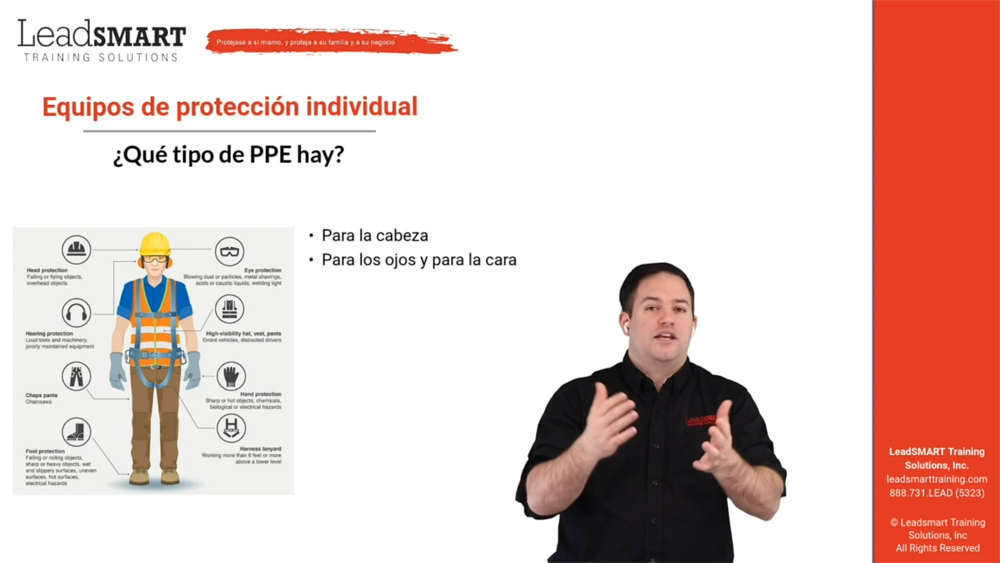

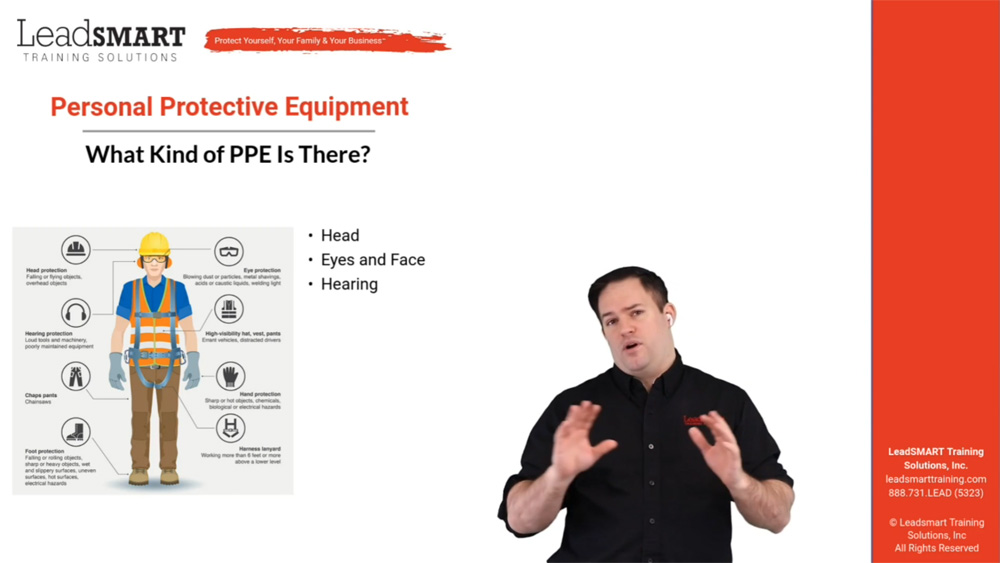

Personal protective equipment, commonly referred to as "PPE”, is equipment worn to minimize exposure to hazards that cause serious workplace injuries and illnesses. These injuries and illnesses may result from contact with chemical, radiological, physical, electrical, mechanical, or other workplace hazards. Personal protective equipment may include items such as gloves, safety glasses and shoes, earplugs or muffs, hard hats, respirators, or coveralls, vests and full body suits. This class will teach the basic OSHA requirements for protective gear every employer must provide for each worker on a construction jobsite.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life!

Video #1 Personal Protective Equipment (PPE)

Personal protective equipment, commonly referred to as "PPE”, is equipment worn to minimize exposure to hazards that cause serious workplace injuries and illnesses. These injuries and illnesses may result from contact with chemical, radiological, physical, electrical, mechanical, or other workplace hazards. Personal protective equipment may include items such as gloves, safety glasses and shoes, earplugs or muffs, hard hats, respirators, or coveralls, vests and full body suits. This class will teach the basic OSHA requirements for protective gear every employer must provide for each worker on a construction jobsite.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life!

Video #1 Personal Protective Equipment (PPE)

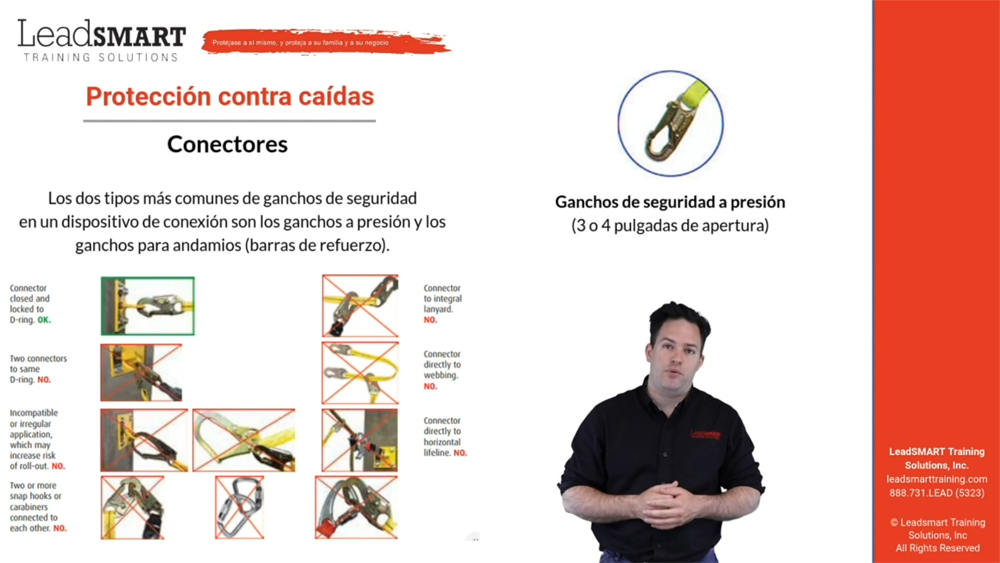

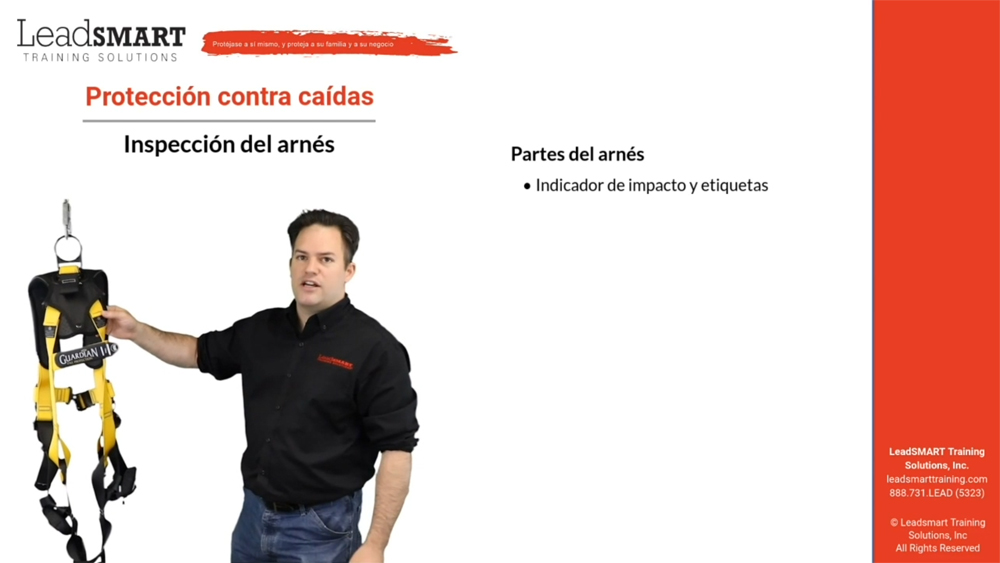

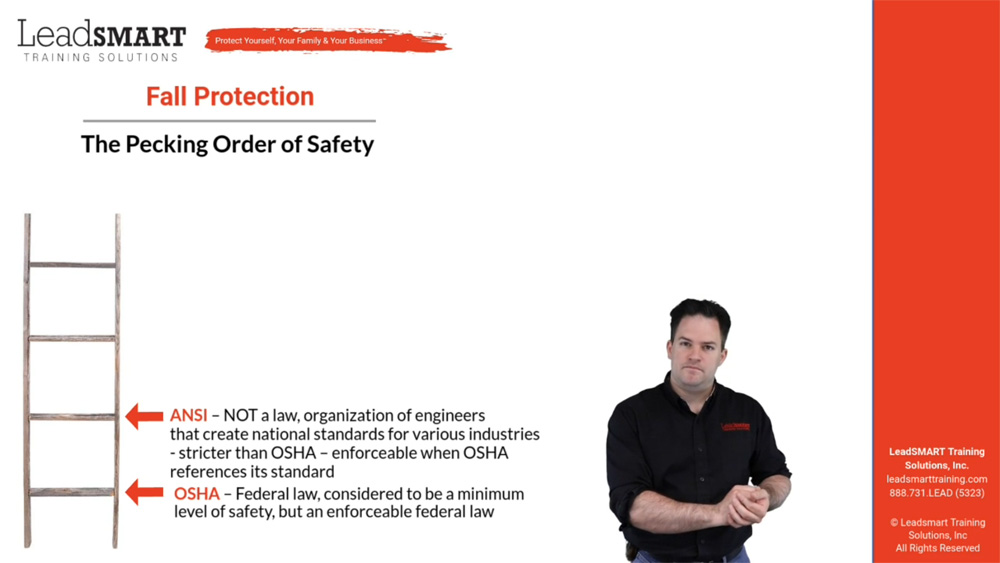

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off overhead platforms, elevated work stations or into holes in the floor and walls.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off overhead platforms, elevated work stations or into holes in the floor and walls.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off overhead platforms, elevated work stations or into holes in the floor and walls.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off overhead platforms, elevated work stations or into holes in the floor and walls.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off overhead platforms, elevated work stations or into holes in the floor and walls.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off overhead platforms, elevated work stations or into holes in the floor and walls.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

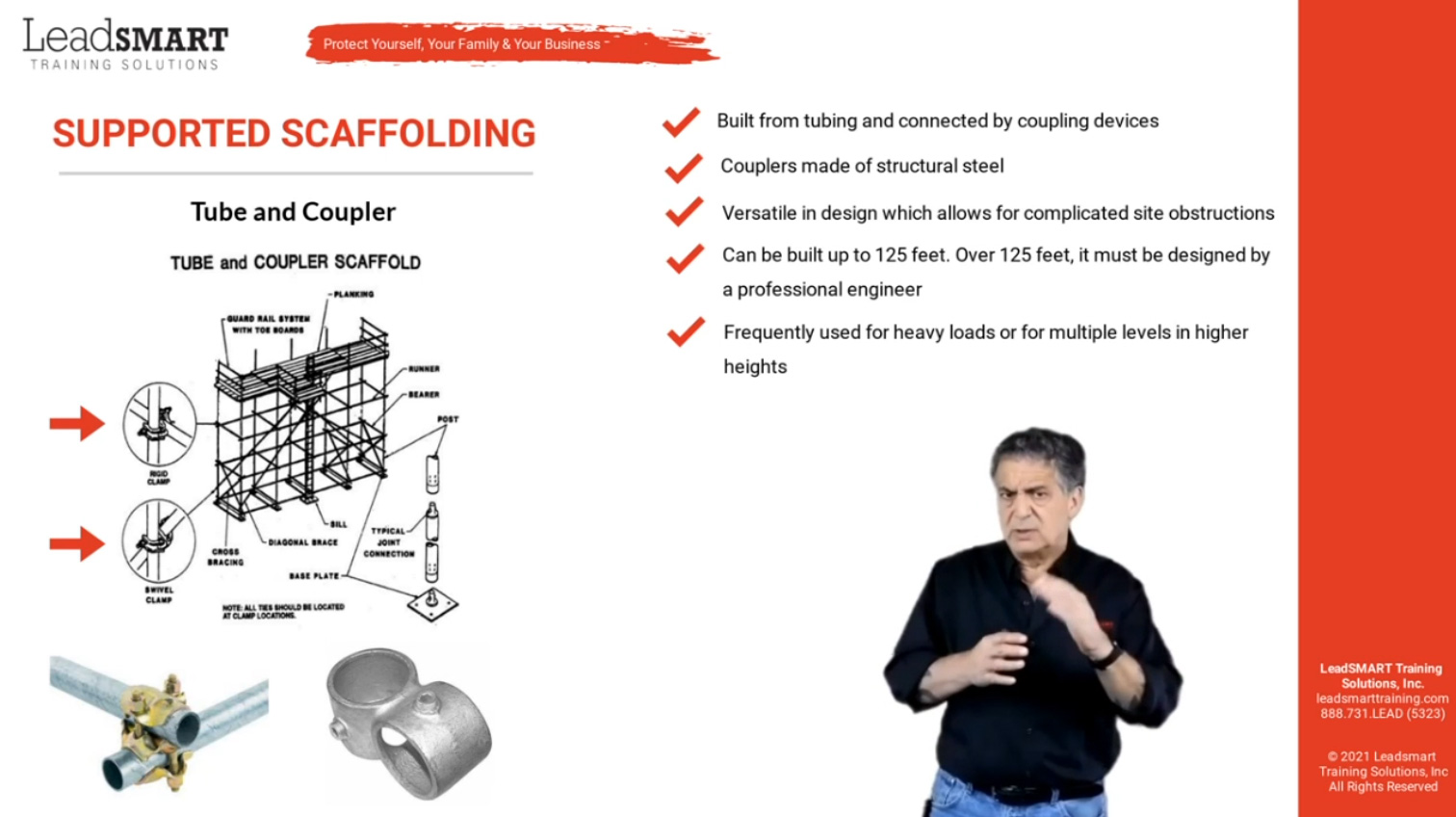

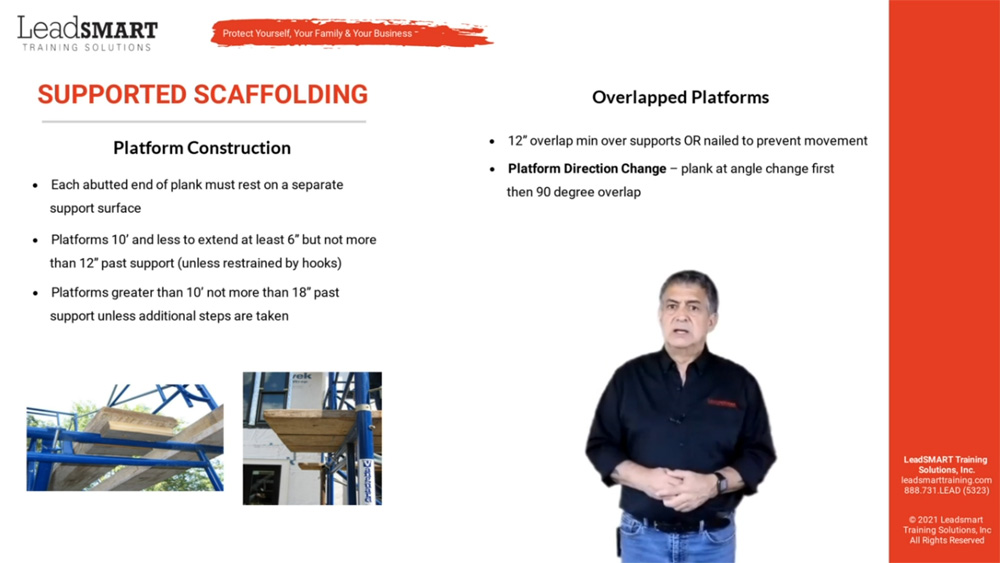

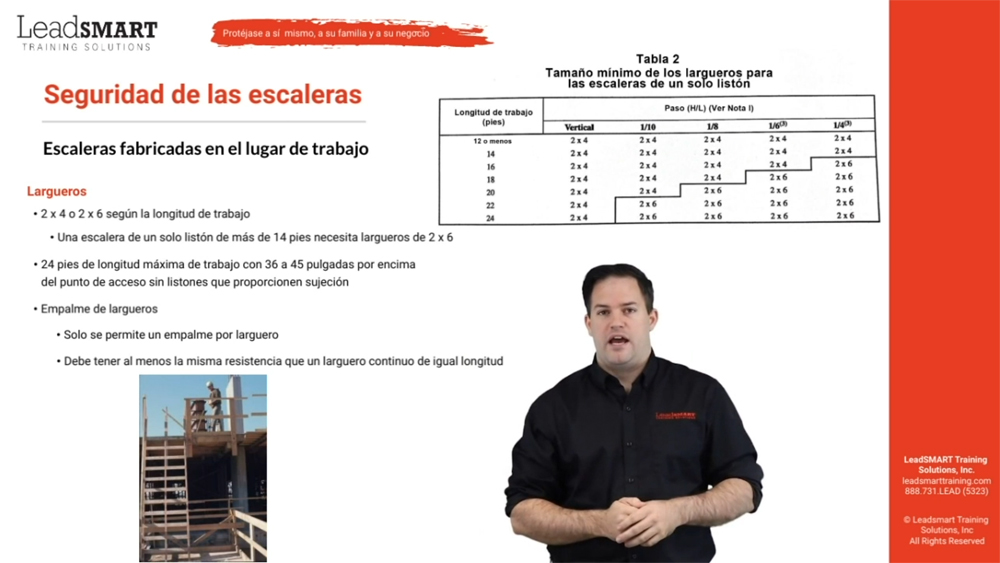

At least 50 deaths and 4500 injuries could be avoided each year with proper training on Scaffolding Safety. Many construction workers use scaffolds daily and face hazards such as bad planking, scaffolding collapse and more. This training will give workers and their Supervisors key information to keep worksites safe.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

At least 50 deaths and 4500 injuries could be avoided each year with proper training on Scaffolding Safety. Many construction workers use scaffolds daily and face hazards such as bad planking, scaffolding collapse and more. This training will give workers and their Supervisors key information to keep worksites safe.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

At least 50 deaths and 4500 injuries could be avoided each year with proper training on Scaffolding Safety. Many construction workers use scaffolds daily and face hazards such as bad planking, scaffolding collapse and more. This training will give workers and their Supervisors key information to keep worksites safe.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

At least 50 deaths and 4500 injuries could be avoided each year with proper training on Scaffolding Safety. Many construction workers use scaffolds daily and face hazards such as bad planking, scaffolding collapse and more. This training will give workers and their Supervisors key information to keep worksites safe.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

CREATED AND RECORDED BY LEADSMART TRAINERS

CREATED AND RECORDED BY LEADSMART TRAINERS

Every worksite using Mobile Elevated Work Platforms – MEWPS – aerial and scissor lifts – must educate workers and supervisors on the latest best practice standards. Ignorance is not a defense and you and your workforce are obligated to understand how each type of MEWP is classified and how it must be controlled when traveling. This training will give workers and their supervisors key information to keep worksites safe.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life!

Video #1 MEWPS

Every worksite using Mobile Elevated Work Platforms – MEWPS – aerial and scissor lifts – must educate workers and supervisors on the latest best practice standards. Ignorance is not a defense and you and your workforce are obligated to understand how each type of MEWP is classified and how it must be controlled when traveling. This training will give workers and their supervisors key information to keep worksites safe.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life!

Video #1 MEWPS

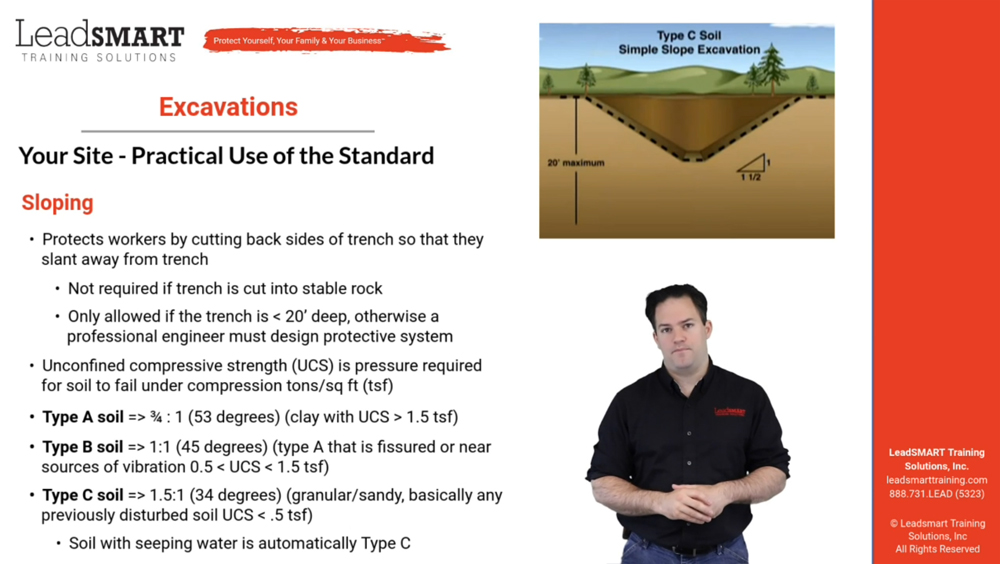

Not a dirt digger? Bet this information will open your eyes about the dangers when you open up Mother Natures home. This video explains the dangers you encounter and how they can change without recognition. Thought provoking – you will be prepared to think ahead before you jump in to your next project.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life!

Video #1 Excavations

Not a dirt digger? Bet this information will open your eyes about the dangers when you open up Mother Natures home. This video explains the dangers you encounter and how they can change without recognition. Thought provoking – you will be prepared to think ahead before you jump in to your next project.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life!

Video #1 Excavations

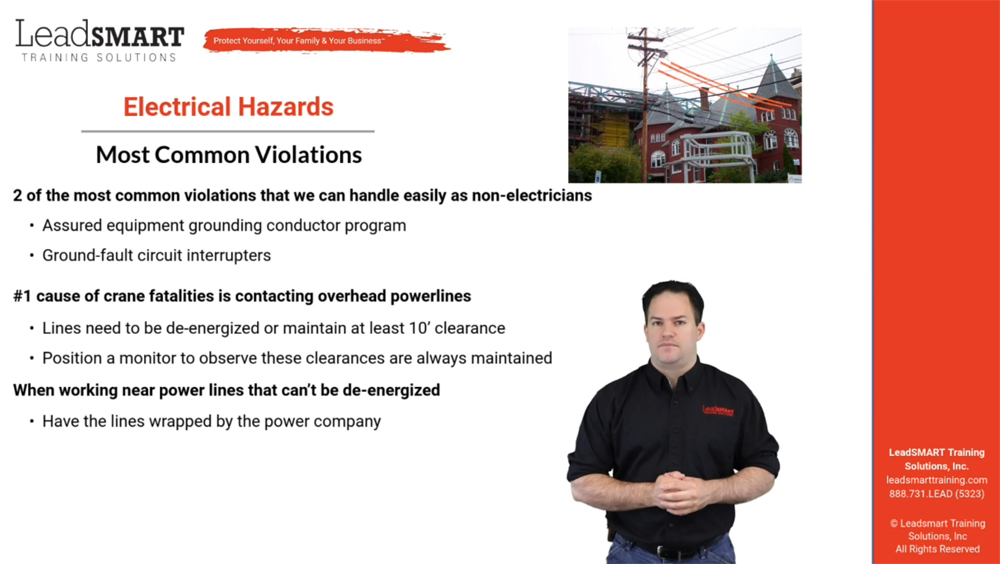

Electrical hazards are often ignored by the workforce due to its lack of warnings other hazards typically come with. It does not have an odor, you can not see it and on jobsites – you wont hear it. Yet it continues to be a major contributor to our workforce – especially those under the age of 25.

This video addresses common hazards we all face in the manner in which we perform our work – we do not address the electrical topics that really pertain to an electrician’s skills or knowledge. This video speaks to the tradesperson working onsite who is not an electrician.

Without this knowledge, you should FEAR electrical power sources. However, with knowledge comes confidence to work in a manner that keeps you safe with electricity.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life!

Video #1 Electrical Hazards

Electrical hazards are often ignored by the workforce due to its lack of warnings other hazards typically come with. It does not have an odor, you can not see it and on jobsites – you wont hear it. Yet it continues to be a major contributor to our workforce – especially those under the age of 25.

This video addresses common hazards we all face in the manner in which we perform our work – we do not address the electrical topics that really pertain to an electrician’s skills or knowledge. This video speaks to the tradesperson working onsite who is not an electrician.

Without this knowledge, you should FEAR electrical power sources. However, with knowledge comes confidence to work in a manner that keeps you safe with electricity.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life!

Video #1 Electrical Hazards

CREATED AND RECORDED BY LEADSMART TRAINERS

CREATED AND RECORDED BY LEADSMART TRAINERS

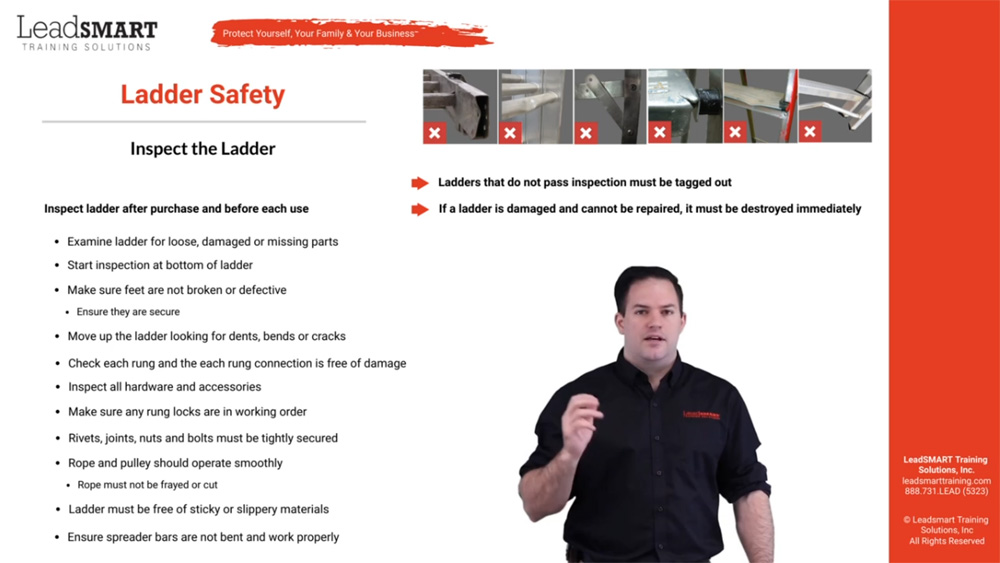

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off overhead platforms, elevated work stations or into holes in the floor and walls.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off overhead platforms, elevated work stations or into holes in the floor and walls.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off overhead platforms, elevated work stations or into holes in the floor and walls.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off overhead platforms, elevated work stations or into holes in the floor and walls.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off overhead platforms, elevated work stations or into holes in the floor and walls.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off overhead platforms, elevated work stations or into holes in the floor and walls.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off overhead platforms, elevated work stations or into holes in the floor and walls.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off overhead platforms, elevated work stations or into holes in the floor and walls.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

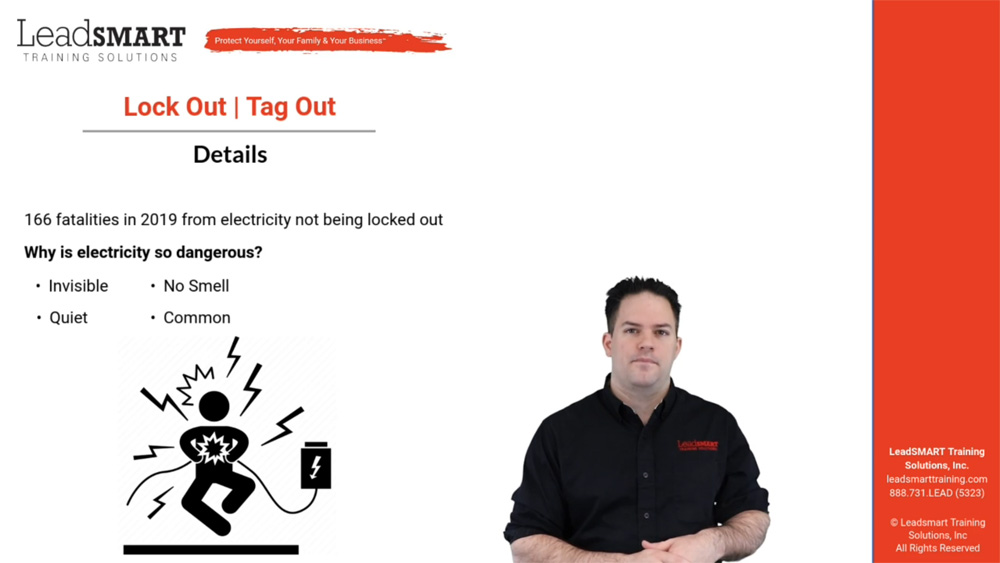

The control of hazardous energy, commonly called a Lockout/Tagout (LOTO) Program, protects workers from injury or death due to the unintended start up or release of stored energy while they are performing maintenance and repair on machines, processes, and systems. The hazardous energy may be electrical, hydraulic, pneumatic, mechanical, chemical, thermal or other sources. Following proper LOTO practices and procedures safeguard workers from hazardous energy releases. This class is required initially and recommended annually for anyone who performs LOTO or is affected by the LOTO process.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life!

Video #1 Lockout/Tagout (LOTO)

The control of hazardous energy, commonly called a Lockout/Tagout (LOTO) Program, protects workers from injury or death due to the unintended start up or release of stored energy while they are performing maintenance and repair on machines, processes, and systems. The hazardous energy may be electrical, hydraulic, pneumatic, mechanical, chemical, thermal or other sources. Following proper LOTO practices and procedures safeguard workers from hazardous energy releases. This class is required initially and recommended annually for anyone who performs LOTO or is affected by the LOTO process.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life!

Video #1 Lockout/Tagout (LOTO)

Personal protective equipment, commonly referred to as "PPE”, is equipment worn to minimize exposure to hazards that cause serious workplace injuries and illnesses. These injuries and illnesses may result from contact with chemical, radiological, physical, electrical, mechanical, or other workplace hazards. Personal protective equipment may include items such as gloves, safety glasses and shoes, earplugs or muffs, hard hats, respirators, or coveralls, vests and full body suits. This class will teach the basic OSHA requirements for protective gear every employer must provide for each worker on a construction jobsite.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life!

Video #1 Personal Protective Equipment (PPE)

Personal protective equipment, commonly referred to as "PPE”, is equipment worn to minimize exposure to hazards that cause serious workplace injuries and illnesses. These injuries and illnesses may result from contact with chemical, radiological, physical, electrical, mechanical, or other workplace hazards. Personal protective equipment may include items such as gloves, safety glasses and shoes, earplugs or muffs, hard hats, respirators, or coveralls, vests and full body suits. This class will teach the basic OSHA requirements for protective gear every employer must provide for each worker on a construction jobsite.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life!

Video #1 Personal Protective Equipment (PPE)

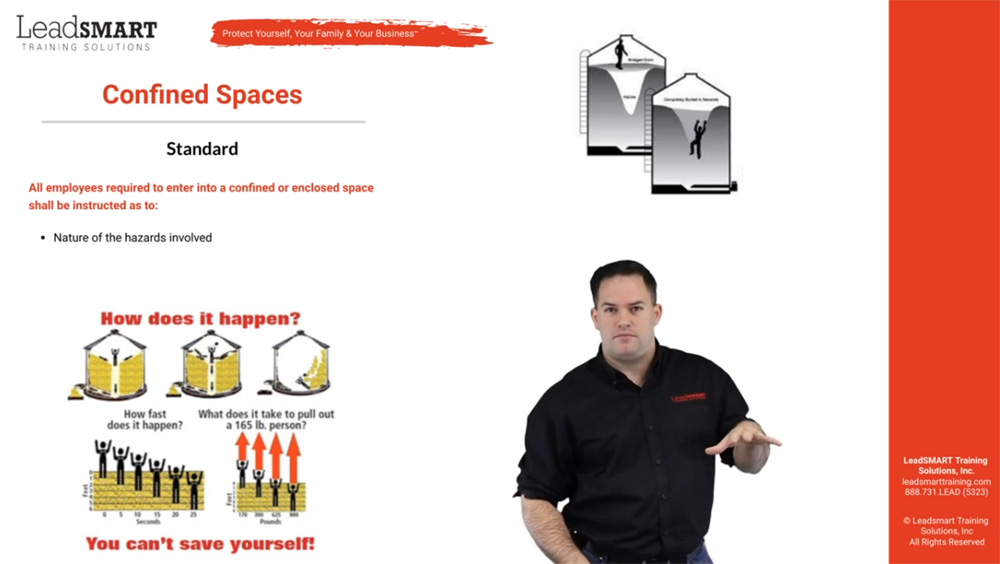

Many workplaces contain areas that are not necessarily designed for people, but they are large enough for workers to enter and perform certain jobs. A Permitted Confined Space also has limited or restricted means for entry or exit and is not designed for continuous occupancy. Permitted Confined Spaces include, but are not limited to, tanks, vessels, silos, storage bins, hoppers, vaults, pits, manholes, tunnels, equipment housings, ductwork, pipelines, etc. These spaces contain or have:

Many workplaces contain areas that are not necessarily designed for people, but they are large enough for workers to enter and perform certain jobs. A Permitted Confined Space also has limited or restricted means for entry or exit and is not designed for continuous occupancy. Permitted Confined Spaces include, but are not limited to, tanks, vessels, silos, storage bins, hoppers, vaults, pits, manholes, tunnels, equipment housings, ductwork, pipelines, etc. These spaces contain or have:

CREATED AND RECORDED BY LEADSMART TRAINERS

CREATED AND RECORDED BY LEADSMART TRAINERS

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off overhead platforms, elevated work stations or into holes in the floor and walls.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off overhead platforms, elevated work stations or into holes in the floor and walls.

Don’t worry, this training isn’t boring. These trainers are contractors too and always keep things interesting…and what you learn could save your life! Everyone should purchase and complete the classes marked “Basic.” All Supervisors should purchase and complete the “Basic” class PLUS all “Advanced” classes.